- #Vectric Vcarve Pro 3D Model Software Solution For

- #Vectric Vcarve Pro 3D Model Skin Of Protective

- #Vectric Vcarve Pro 3D Model Full Control Of

Vectric Vcarve Pro 3D Model Software Solution For

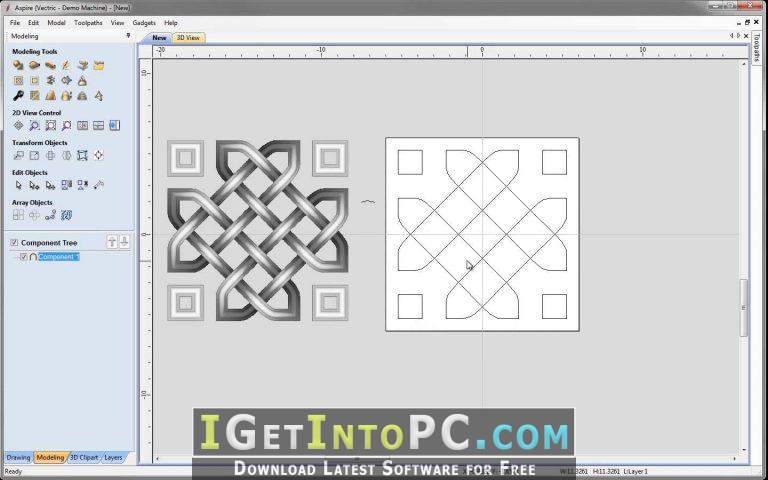

The ‘Desktop’ edition is designed for small CNC machines, aimed at hobby or non-production environments.VCarve Pro License Code also supports Windows drag-and-drop functionality to quickly add 2D or 3D clip art to existing models directly from Windows Explorer. VCarve Desktop gives you the power to produce complex 2D patterns with profile, pocket, drill and inlay toolpaths, plus gives you the ability to create designs with v-carving textures as well as import and machine unlimited Vectric 3D clipart or single model files. Vectric is the company that produces VCarve Desktop, VCarve Pro and Aspire.VCarve Desktop provides a powerful but intuitive software solution for creating and cutting parts on a CNC Router. In addition to the powerful drawing and production routing tools of VCarve Pro, Vectric Aspire 9 Serial Key also has tools to let you transform 2D sketches, photos, drawing and digital artwork into detailed 3D relief models and then to calculate 3D Roughing and finishing toolpaths to precisely cut these shapes.exceptional at creating tool paths for 3D models that are imported from.

Vectric Vcarve Pro 3D Model Full Control Of

Lead In / Out and Overcut distance to prevent dwell marks appearing on components Angular "3D" Tabs for smoother profiling plus advanced options for automatic positioning to hold parts in place when machining Full control of cut direction is offered along with either automatic or manual control of tool entry point for each shape.Profile Machining includes production cutting options that ensure parts can be held in place and accurately machined with high quality edges and corner detail. The Profiling automatically offsets for the tool radius and sorts nested shapes to ensure that inner shapes such as the center of a letter 'O' are cut before the outer shape (so parts are not released from the material before they are cut). Simply select the vector shapes you wish to profile, select the tool from the tool database and the software will do the rest. In addition to the large number of files that are included with the software (see Free Clipart section below) Vectric also has a website that offers additional files for sale Using the profiling toolpath strategy, objects can be cut out quickly and efficiently.

The software has been structured to let you customize whether you just want simple options for quick cut-outs or whether you want to access more advanced features to control cutting on particular material. It is used for some of the simplest and also the most complex things you may do with your CNC. This is often used when profiling with a V-Bit tool, where with a conventional toolpath the tool will 'roll' round a sharp external corner leaving a radius on the chamfer created by the tool, with the 'square corners' option an angular chamfer will be created.The Profile toolpath is probably the most important toolpath option available. The number of passes on a cut can be edited very precisely to allow very thin final cuts or to individual add or remove particular cut depths.A very powerful feature is the ability to specify that square corners are required. Sharp internal and external beveled edges and cornersCutouts can be done in multiple passes depending on the maximum cutting depth of the tool used and a positive or negative allowance can be specified to either 'under cut' or 'overcut' the shape if required. Profile around the Outside / Inside of open shapes

To give these textures a more natural and less machine made look you can set different levels of randomness. Vectric has a unique approach to generate unique 'hand carved' looking textures which still machine extremely efficiently.Once you specify a tool (typically a pointed or round profile) then you have various settings you can set to create the characteristics of your texture toolpath. This is done automatically by the software when the carved area is deeper than the maximum cutting depth of the tool.Textured panels are often specified by interior designers and architects and textures are also a very useful option for creating backgrounds on dimensional signs. For some applications this can help reduce the load and as such potential marking of the finished part, created by tool vibration when plunging into a deep area.Another advanced capability is the support for VCarving areas wider than the tool by making multiple clearance passes to achieve the required depth. The software automatically calculates a path defined by the combination of the angle of the tool specified and the width and shape of the vectors being machined.The extremely fast and robust Vectric VCarving engine handles complex designs with ease providing both fast calculation speed and robust handling of imperfect data.As well as 'simple' VCarving, the software supports many advanced VCarving strategies, such as 'Flat Bottomed' v-carving, optionally using a second flat bottom tool to optimally clear out the flat areas.The option to Use Vector Start Points lets you choose the positions the tool will enter the material.

Vectric Vcarve Pro 3D Model Skin Of Protective

Depending on the shape of the part there is a choice of Raster and Offset cutting strategies.Detailed regions can be machined selectively using smaller cutters to ensure the finest of detail on a 3D project is accurately machined.The conventional 2D / 2.5D toolpath strategies in VCarve software can also be projected onto an underlying 3D model surface. The tool parameters let you balance the quality of the surface finish with how long the part will take to cut. The toolpath also has an option to specify an allowance to leave a skin of protective material on the part for the finish cut to clean up.3D Finish Machining cuts the 3D part of the job to the exact size. There are two Roughing strategies available Z-Level and 3D Raster each of these has advantages depending on the type of shape being cut.

This means that whether your job is a simple toolpath with one tool, or created from a complex combination of tools and strategies at different levels you can be sure that when the job is cut, it is right first time.As well as showing that the toolpaths are correct, the high quality rendering and ability to use real world material textures and fill colors is a very valuable sales tool. The results of each individual or the combination of all the toolpaths can be previewed cutting into a 3D preview model. Pocket, Profile, Drill and Texture onto the 3D modelOne of the most important productivity tools available in the software is the realistic 3D toolpath preview support. VCarve or Engrave at constant depth onto a 3D surface

0 kommentar(er)

0 kommentar(er)